EX series Explosion-proof Sewage Submersible Pump

Explosion-proof Sewage Submersible Pump: EX series

■ FEATURES

- Certificate: Taiwan TS explosion-proof unit certification, Zone 1 and Group IIB T4 standard.

- Special sealed and designed pressure-proof and explosion-proof motors for preventing the external structure from exploding due to explosion pressure when the gas in the motor casing is detonated.

- Motor specification: IE4(Super Premium), insulation grade F (155°C) of dry induction motor, explosion-proof grade Ex db h IIB T4 Gb.

- ”External Tem. Control wire” &” Auto-cut” which prevents the motor from overheating.

- Thick EPOXY coating is better corrosion-resistance and rust-resistance.

■ APPLICATION

- In a hazardous area such as Zone 1, Group IIB T4, the gas, vapor, or mist, and the mixture of air will turn the environment into an explosive environment, which may be used in common circumstances and places where it may exist.

- It is used in closed areas with biogas, chemicals, flammable, explosive gas, dust, etc.

- Suitable for industrial and agricultural wastewater discharge, chemical, petroleum, mining, power plants, sewage treatment plants, sewer systems, and livestock farms.

■ STRUCTURAL DRAWING

■ DIMENSION

■ MATERIAL AND STANDARD TABLE

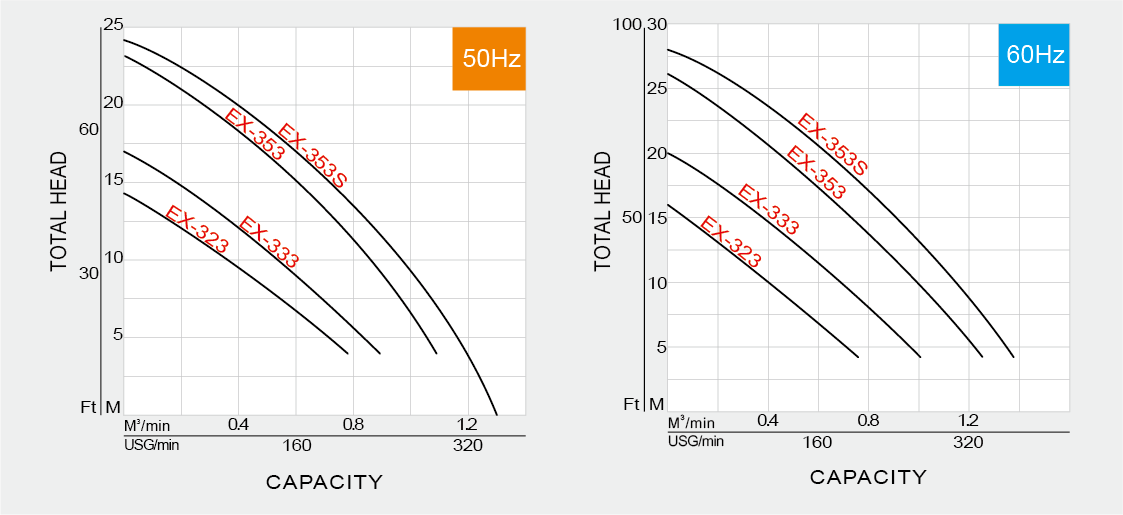

■ PERFORMANCE CURVE

■ SPECIFICATION

| TYPE | FREQ. | PHASE | POWER | DISCHARGE | POLE/ROTATION | STD.HEAD | STD.FLOW | MAX.HEAD | MAX.FLOW | WEIGHT |

SOLID PASSAGE |

|||||||||

|

Hz |

PH | HP | kW | INCH | MM | P/RPM | M | M3/min | M | M3/min | KG | MM | ||||||||

|

EX-323 |

50 | 60 |

3Φ |

2 | 1.5 | 3" | 80 | 2P | 2850 | 3450 | 11 | 11 | 0.30 | 0.30 | 14 | 16 | 1.00 | 1.00 | 55 | 40 |

| EX-333 | 50 | 60 |

3Φ |

3 | 2.2 | 3" | 80 | 2P | 2850 | 3450 | 12 | 13 | 0.40 | 0.50 | 17 | 20 | 1.10 | 1.20 | 57 | 40 |

|

EX-353 |

50 | 60 |

3Φ |

5 | 3.7 | 3" | 80 | 2P | 2850 | 3450 | 17 | 19 | 0.50 | 0.50 | 23 | 26 | 1.20 | 1.40 | 60 | 40 |

|

EX-353S |

50 | 60 |

3Φ |

5 | 3.7 | 3" | 80 | 2P | 2850 | 3450 | 18 | 22 | 0.50 | 0.50 | 24 | 28 | 1.35 | 1.50 | 60 | 35 |